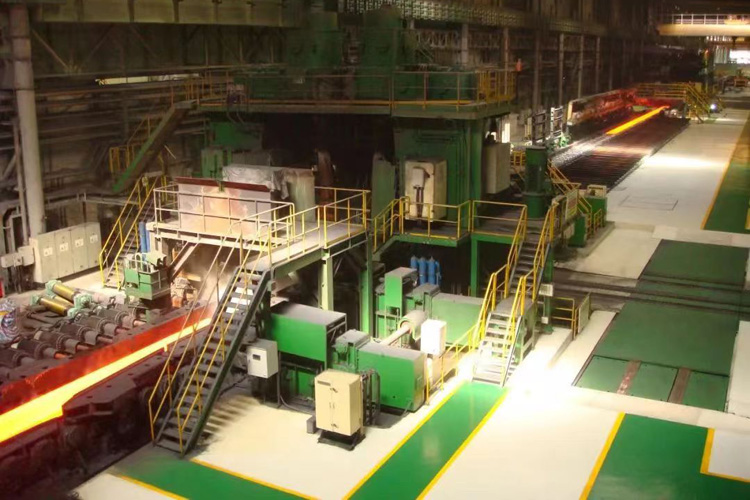

Hot rolling machinery

Hot rolled strip machinery, hot rolled wide strip:

1. Process description: The steel billet is heated to a certain temperature through a heating furnace, and after phosphorus removal, it enters the bloom rolling mill for repeated rolling. After repeated rolling, it passes through the rough rolling mill for repeated rolling, and then passes through the vertical rod rolling mill for fixed width rolling. After that, it is processed through 7-13 continuous rolling to produce finished rolled products

2. Equipment Composition:Walking beam heating furnace - rear roller table - high-pressure water phosphorus removal - fixed width device - bloom rolling mill - front and rear turning roller table - rough rolling mill - vertical rod rolling mill -7-13 sets of precision rolling mill - oscillator - air cooling bed - vertical winding mill

3. Technical specifications: Hot rolled strip steel 145-650mm, designed according to customer requirements for material, width, thickness, rolling range, etc.

Send Inquiry